The current average for recycled content across all packaging in Australia is 35%. This average includes current recycle rates for paper – 49%, metal – 30%, and glass 32% with targets to increase to 60%, 35% and 50% respectively.

The inclusion of recycled content for soft plastics must increase by 18% in the coming three years to reach a 20% average and this must be achieved primarily without recycled content being in contact with food.

Can it be done?

There’s work to do. Designing recyclable packaging is critical to creating a supply of recycled materials.

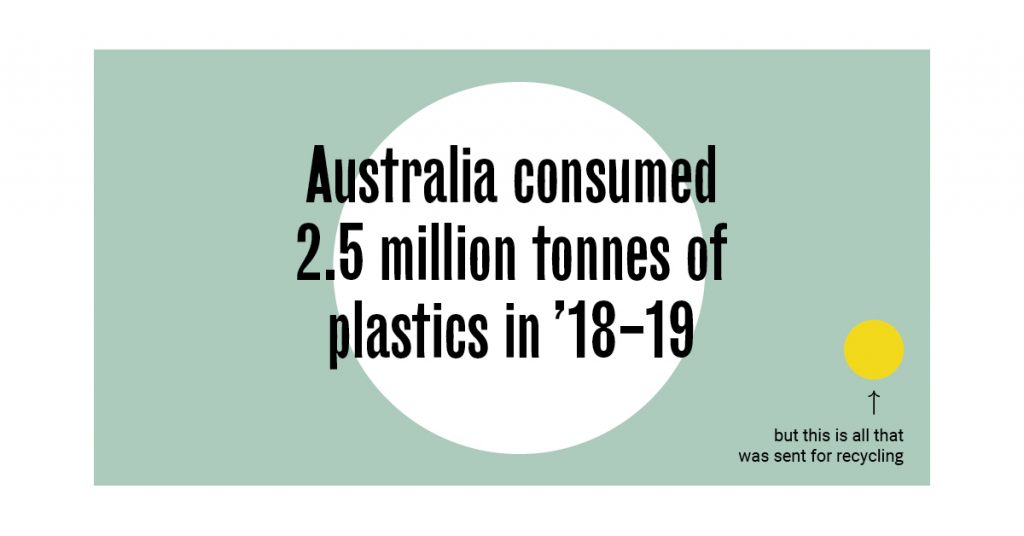

Recycled content, PCR (post-consumer polymer) is generated from effective kerbside collection and sorting ‘recycling’. The basic infrastructure is in place, significant public and private investment is giving a much-needed ‘turbo charge’ to bring up sorting standards and efficiency. National programs on this scale, including multiple stakeholders will take time to generate the required quality and volume of recycled materials for re-inclusion in packaging. Up until recently only 2% soft plastics were recycled onshore in Australia so the required ‘turn around’ Is significant!

By comparison, Europe sees recycling rates of plastics at 35%, with targets to recycle 55% by 2030. Europe’s target is 30% inclusion of post-consumer recycled content as an average within soft plastics.

Use of recycled soft plastics (PCR) in direct contact with food is not possible at scale in soft plastic packaging due to increased contamination risk. One solution to this problem will be chemical recycling, this technology will scale over the next two decades, but with the incumbent mechanical recycling infrastructure in place , it’s not currently a viable option. This is not the same with glass, PET, metals as these material groups are taken back to original form.

How will we achieve our 20% inclusion target for soft plastics by 2025 in Australia as a truly circular solution for the packaging industry? Through broad adoption of up to fifty per cent inclusion of PCR (Post-Consumer recycled polymer) across all non-food contact plastics, including agriculture, industrial applications, wraps, chemicals including semi rigid plastic containers.

PCR inclusion should complement the transition to mono-material applications, we should look to avoid mixed polymer structures as well as utilising PCR.

Advancement of technologies is allowing effective use of recycled polymers at reduced gauges; multi-layer co-extrusion allows recycled content polymers to be ‘sandwiched’ in film structures to reduce impact on mechanical performance.

There are several reasons why using recycled content is beneficial to packaging manufacturers, brand owners, the economy, and the environment, including:

“A circular economy is a systemic approach to economic development designed to benefit businesses, society, and the environment. In contrast to the ‘take-make-waste’ linear model, a circular economy is regenerative by design and aims to gradually decouple growth from the consumption of finite resources” – Ellen Macarthur Foundation

Inclusion of recycled content, in particular PCR polymers embodies the circular economy principle, whilst only one aspect of the overall value chain it’s a critical building block in the process.

The Global Plastic Recycling Market is estimated to be USD 45.5 Bn in 2021 and is expected to reach USD 65.3 Bn by 2026, an increase of 45%. This rate of acceleration is significant in terms of market growth and reflects positive change in response to circular economy demand, this growth is supported by both private and public sector initiatives working together with some clarity about the challenges faced by society.

Labelling of materials through ARL, OPRL and or similar schemes is being adopted and, in some cases, mandated for in most developed economies. Consumer education, clear and consistent instructions about recycling, will further streamline the capture and sorting process.

Cyclpac works with manufactures, producers and growers to building responsible packaging solutions for the circular economy, let’s start a conversation.

– Edward