Clear timelines are in place in most developed economies to ensure all soft plastics can be recycled, reused, or composted.

1. To protect

Encapsulate the product to ensure it arrives in a safe fit state for consumption or use.

2. To preserve

Minimise degradation of the product during shipment and storage.

3. To extend

Maximise shelf life to minimise waste, this is critical in respect of food waste.

4. To communicate

To encourage customers to reduce food waste, recycle.

How can we meet these needs while also reducing our environmental impact? The emerging guidelines coming from the industry focus on polyolefin-based flexible packaging (mono-PE, mono-PP, PET) because these material groups make up the largest proportion of the post-consumer flexible packaging waste stream. Additionally, the ability to sort and mechanically recycle these materials is already proven at industrial scale.

Industry guidelines contain information and practical advice on designing polyolefin-based flexible packaging to be recyclable, covering the key elements of a flexible packaging structure. This includes setting limits on some materials and elements, to enable designers to maximise the ‘sortability’ and ‘recyclability’ of their flexible packaging.

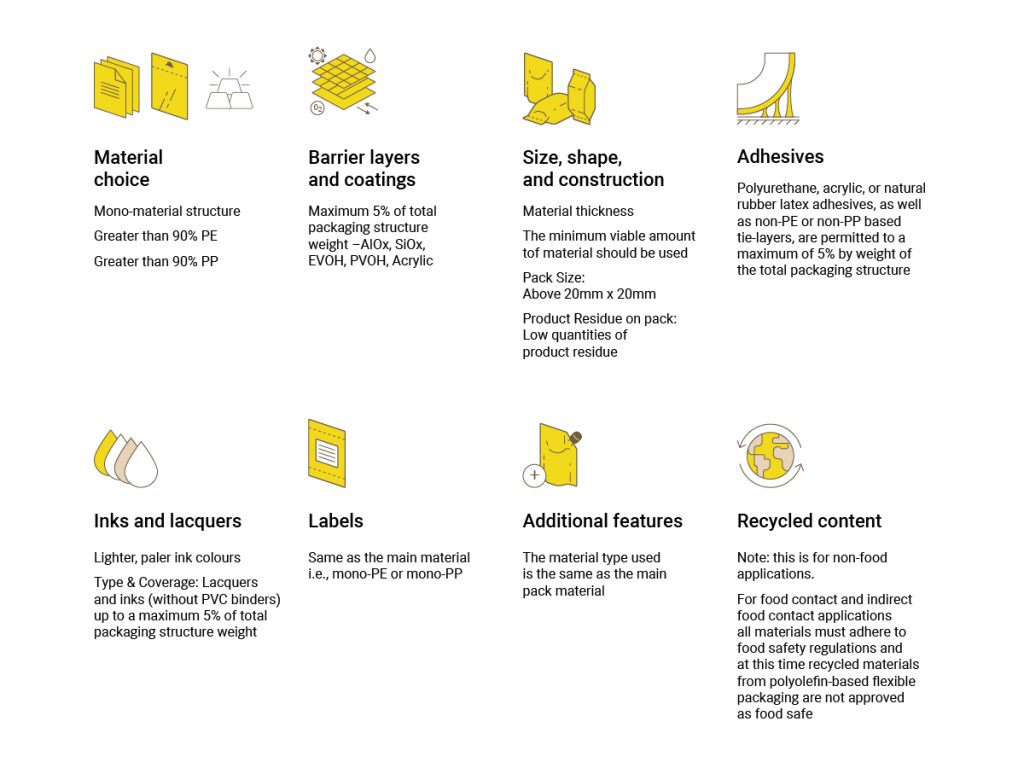

Material choice

The materials used in flexible packaging influences how the packaging is identified when disposed of, and how it is managed in the waste stream. Mono-material packaging is currently preferable to mixed materials, as these are easier to recycle and contribute to an improved quality of recycled materials. For polyolefin-based structures the guidelines recommend the use of mono- PE and mono-PP structures.

Most important: Mono-material structure, Greater than 90% PE and Greater than 90% PP.

Barrier layers and coatings

Barrier materials and coatings are an important element of many flexible packaging structures, providing functionality and reducing overall use of materials and resources. The guidelines provide limits for these elements to ensure the choice of barrier material and the amount used does not adversely affect recyclability.

Most important: Each barrier layer and coating maximum 5% of total packaging structure weight.

Size, shape, and construction

The size, shape and construction of the pack determines how it behaves in a waste sorting facility. For example, packaging that is too small is likely to fall through holes in screening equipment and end up being sent for energy recovery or landfill. While packs should not be made bigger just to facilitate ‘sortability’, the guidelines offer advice on shape and construction to aid the sorting process.

Most important: The minimum viable amount of material should be used, low quantities of product residue are key.

Adhesives

Adhesives play an important role in combining multiple layers of the same (or different) materials. The total amount of adhesive used should be below specific thresholds to prevent it negatively impacting the recyclate quality.

Inks and lacquers

Printing of flexible packaging provides important product information to consumers, as well as barrier properties. Coverage levels of printing and colours of inks and lacquers can impact the recyclability and the quality of recycled materials.

Most important: use light, pale colours, up to 5% of total weight, surface or reverse.

Labels

When printing is not viable, labels can be used. Stick to the main material.

Additional features

The guidelines advise that the materials used for packaging features such as zippers, spouts, closures, and valves should be the same as the primary pack material.

Recycled Content

The use of recycled content in flexible packaging to reduce the use of virgin material and create markets for recycled materials is encouraged, with an increasing focus on PCR (post-consumer recycled) polymers. Note that this is for non-food applications. For food contact and indirect food contact applications all materials must adhere to food safety regulations and at this time mechanically recycled materials from polyolefin-based flexible packaging are not approved as food safe.

As we move toward the circular economy, all parts of the flexible packaging value chain have a vital role to play. Now is the time to review existing flexible packaging portfolios against these guidelines. Cyclpac can help you with this.

As an industry we need to constantly evaluate what changes can be made to further improve and optimise the design and end-of-life sorting and recycling processes for structures that do not currently fulfil the requirements for today and tomorrow.

It is critical the whole value chain adopt these guidelines as a tool when designing and specifying new flexible packaging structures. Adoption of these design principles will increase the amount of recyclable flexible packaging on the market and this, in turn, will encourage increased collection. This will mean more becomes available for sorting and recycling, which will improve the quantity and quality of flexible packaging recycled, this quality of recycling will generate consistent PCR (Post-consumer recycled) polymers for re-inclusion and there for reducing the requirement for virgin polymers.

The next step is to further develop solutions for those flexible packaging structures not yet fully addressed or covered. These include those flexible packaging structures using more complex combinations of materials, barrier layers and other elements to better understand if and how these flexible packaging structures that are not currently being sorted and recycled, can be.

Constant review of the guidelines is critical, we must not lose sight of the fact that the capabilities of sorting systems and mechanical recycling are developing significantly because of continued investment by governments, local authorities, and private enterprise. Designing for a circular economy will expedite the economic opportunities for existing and new stakeholders. What is not possible today, might well be common practice tomorrow as this investment comes online.

Cyclpac can help your business to develop a sustainable road map in a couple of simple ways:

1. Education & conversation, working with your teams, discussing the guidelines and principles of the circular economy, helping to prioritize actions for your business

2. Packaging & process audit, collect base line data, understand your businesses from a packaging, process, and market perspective, set some practical objectives and timelines for change, developing alternative solutions, working with you in each phase of transition

— Edward.