BOPE and BOPE film is a big step forward for flexible packaging as it supports brand owners in their quest to design packaging for the circular economy.

Mono structure applications promote efficient recycling of the most broadly recycled soft plastic PE. Blown polythene has its place in the industry for the foreseeable future but unless it’s adding value to structure development or technical advancement of packaging we have better alternatives now.

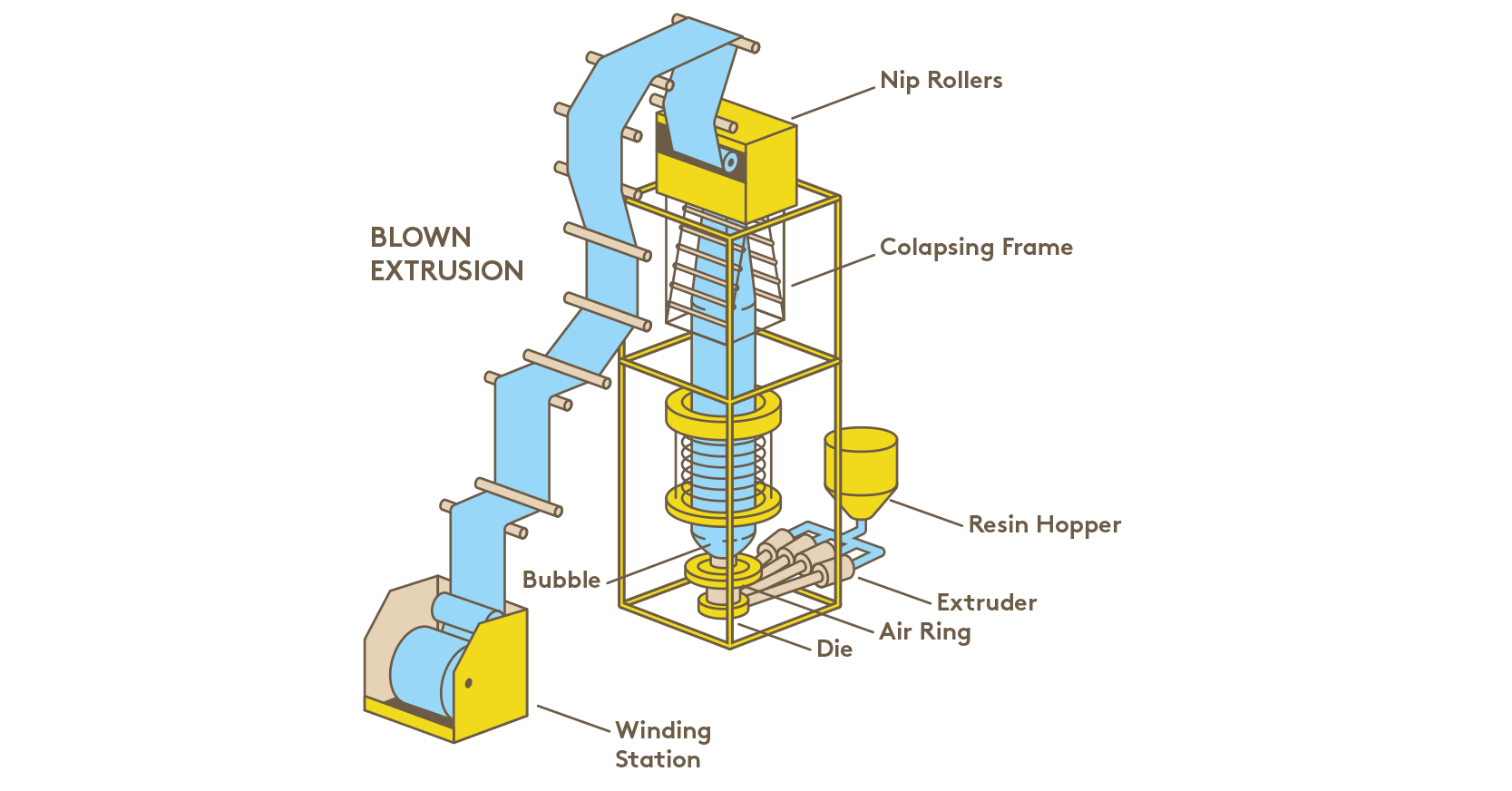

Blown films, sometimes referred to as tubular films, are manufactured by extruding molten resin vertically through a circular die. Introducing air through the centre of the die creates a bubble. The air drives the bubble upward, and slowly cools the material. Nip rollers flatten the material into a tube that can be reeled for creating bags and pouches, or slit and then reeled as a flat sheet of film. Blown films are pre-stretched by virtue of their manufacturing process.

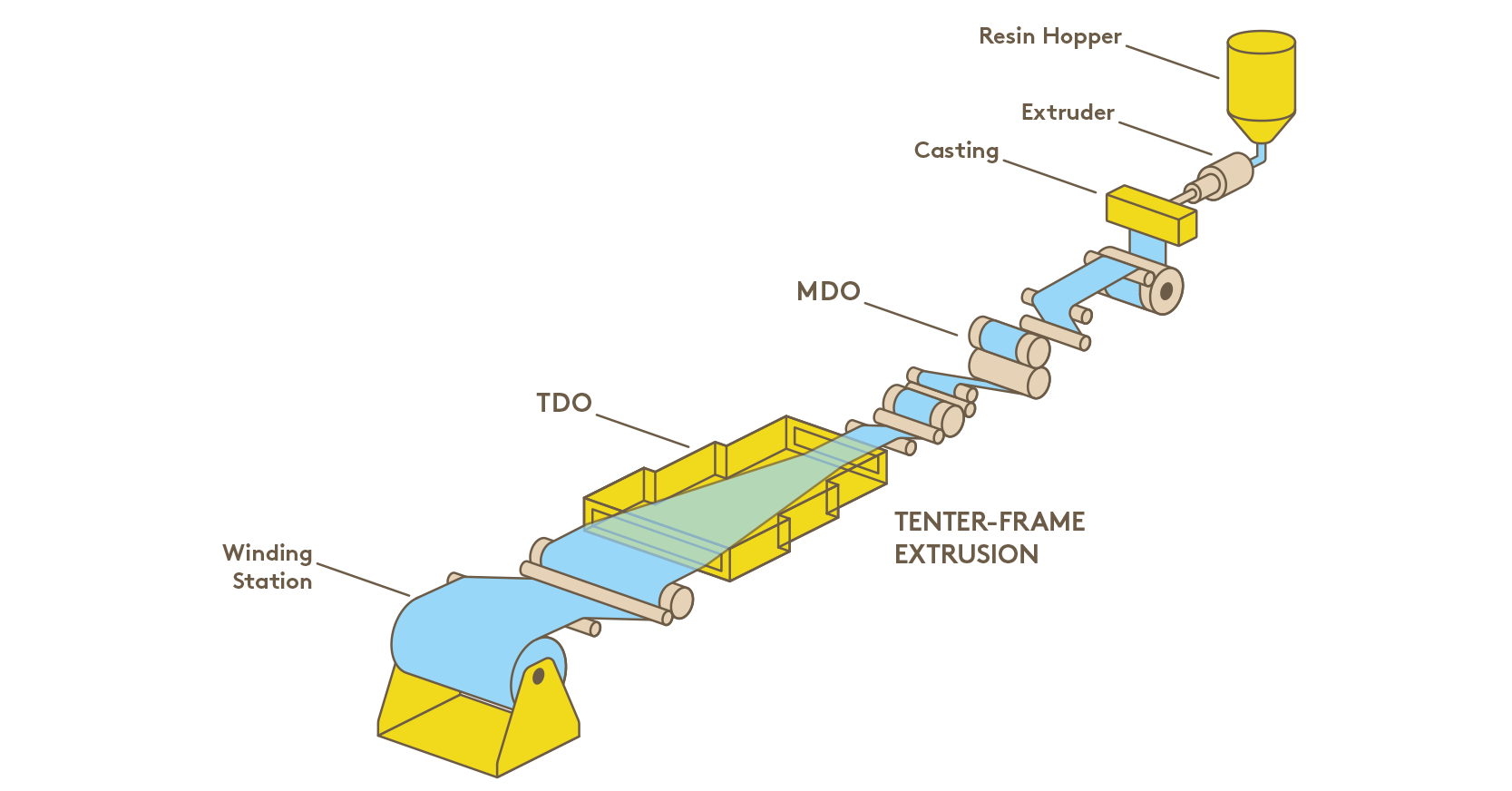

Bi-Orientated Extrusion (Tenter Frame) is different, made by extruding melted resin horizontally through a flat die then casting a relatively thick film from the co-extrusion process through a slot die and rapidly cooling it. The film is then drawn, stretching the film in the machine direction using a stack of heated rollers, each rotating at speeds progressively faster than to stretch the film structure. The same process is applied in the cross direction. A relatively thin film is created under uniform MD and TD tension. Typically, biorientated films have an even distribution of polyolefins due to increased gauge consistency in the manufacturing process.

The two processes look very different.

The Blown process is vertical with stacks reaching 30+ metres high in a high ceiling extrusion hall

Bi-orientated production is horizontal with a production hall in excess of 100m long to accommodate huge machines.

There are other significant differences between the two also.

Optical properties

BOPE is comparable to BOPP in terms of optical clarity where traditional PE is hazy and opaque at times. For food packaging products this makes a huge difference where shelf appeal and shopper confidence matters. Film clarity and gloss is attributed to the shish-kebab type of crystals created during the stretching process and the stable flat surface this creates.

Puncture and tear resistance

Compared with blown PE, BOPE outperforms conventional PE in some key areas. BOPE has a puncture resistance that outperforms blown PE x2.3. Dart Impact testing in a lab environment has shown BOPE film to outperform blown PE x1.9 in drop tests. This critical data supports the use of BOPE as primary packaging for e-commerce ordering, providing strength and light-weight performance avoiding the need in many instances for secondary packaging.

Due to BOPE’s superior heat resistance and strength compared to traditional blown PE we are seeing increasing utilisation and inclusion in mono structure packaging replacing conventional materials such at BOPP, PET and BOPA.

Downgauging

Due to the elasticity of BOPE compared to blown PE (modulus) 1.8x improvement in MD (machine direction) ad 2.5x improvement in TD (transverse direction) we have significant potential to downgauge. Removing packaging weight is a priority for any brand owner especially without compromise to packaging performance, sealant layers, abuse layers in laminated structures can be reduced by 55% in some instances.

BOPE’s technical performance when compared to blown PE provides some significant advantages in many areas, brand owners and manufacturers benefit from a flat surface for printing that works on both gravure and flexo printing presses, strength, clarity and significant downgauging opportunities. Heat resistance enables lamination and conversion processes to take place with minimal adjustment, which in turn promotes designing for the circular economy and using materials that are easily recycled.

Most crucially BOPE is 100% recyclable, we can reduce how much we use in primary packaging because of the downgauging opportunities and what we do use can be recycled through effective collection.

Multi-Layer ‘smart films’ the future of blown extrusion

Blown PE has served the packaging industry well at a base level. The evolution of blown film technology means we can now produce ‘smart films’ , blown co-extruded substrates with, 5, 7, 9, 11 layers, providing technical barrier, stiffness, COF (coefficiency of friction) not seen before. Working with these smart films in combination with BOPE we can create packaging which is easily recycled and most critically supports extending shelf life of precious food and other commodities we package and promote.

If you’d like to try our BOPE on your next product run, reach out.

I’d love to help with what you’re working on.

Edward